Artificial intelligence and logistics is the perfect union for businesses seeking a competitive edge – and a necessary combination for companies hoping to compete in the future.

Let’s go inside the technology of AI and logistics. First, supply chain management, or SCM, is the process of overseeing the shipping process. Logistics is the portion of SCM concerned with the movement of goods. For many years, technical advances in logistics has lagged behind other industries.

A major reason for this lag is the sheer number of people and companies that even a single supply chain serves: developers, manufacturers, brokers, retailers, transportation companies, and customers. Giant retailers like Walmart or Amazon could impose technical requirements on some of their partners but not all. And at many stages in the supply chain, enabling technology did not exist.

Today that is changing as artificial intelligence-driven logistics spearhead a fundamental transformation in the global movement of goods.

Top Three AI and Logistics Trends

In DHL’s Logistics Trend Radar, DHL predicts three major trends driving logistics innovation: self-driving and unmanned vehicle technology, the Internet of Things (IoT) and logistics driven by AI and machine learning.

● Transportation. Autonomous logistics is the science behind self-driving vehicles on the roads and unmanned aerial vehicles in the sky. This trend leads to people picturing sky driving scenes from The Jetsons, but unmanned flights deliver critical goods today to remote islands and mountain regions. And Google and a few other companies are pouring resources into developing self-driving vehicles for delivering goods.

● Internet of Things (IoT). Analysts forecast that over 50 billion objects will be connected to the Internet by 2020. Since IoT can connect between the Internet and data-driven logistics, it may be a fertile area for artificial intelligence and logistics. However, most current IoT applications are for the consumer market. The business sector requires industry standards and strong security measures that are not necessarily present the consumer market. This may change and IoT is presently in use in some specific environments, such as adding sensors to physical stock in warehouses to track inventory.

● Artificial intelligence and logistics. In contrast to IoT, businesses are making great strides with artificial intelligence, machine human interaction, and logistics collaboration. Robotics and automation are a primary sector for AI and logistics. Although manufacturers have an interested in industrial robots for some time, complex logistics operations and high robotics costs formed barriers to adoption. Today costs are going down and robots are more flexible and easier to program, making them cost-effective in repetitive and physically demanding logistic tasks. Another example of artificial intelligence and logistics is the retail shipping channel, also called the omni-channel. Omni-channels comprise multiple companies and consumers in a supply chain. Consumers understandably want the fastest possible delivery at the lowest possible price. Retailers want to offer very fast delivery as a competitive option, but must retain an acceptable profit margin. Artificial intelligence enables logistics professionals to cost-effectively accelerate delivery.

Major Trends in Artificial Intelligence and Logistics

DHL identifies two of the biggest usage trends in AI and logistics: anticipatory logistics and self-learning systems.

Trend: Anticipatory Logistics

Anticipatory logistics are based on predictive algorithms running on big data. The practice allows logistics professionals to improve efficiency and quality by predicting demand before a consumer places an order.

The primary driver for anticipatory logistics is customer impatience with long delivery times. Customers want their online shopping convenience to be matched by fast delivery speeds. Anticipatory logistics benefits all entities in the supply line by anticipating demand; enabling businesses to ramp up resources before the demand spikes.

For example, if the AI predicts consumer demand for a computer tablet, then the manufacturer ramps up production with reasonable certainty. Trucking companies know in advance how many trucks they need to deliver the tablets on what dates. The retailer knows to order sufficient stock, to ramp up advertising and display space on its shelves, and to prepare for a spike in online ordering.

Anticipatory logistics also serves supply chain risk management. AI predicts maintenance needs and potential risks, similar to transportation and disruption management predictions. Manufacturing and transportation industries use AI to predict factory and vehicle maintenance. In this case, predictive maintenance is based on sensor data gathered from smart machines and vehicles.

For example, a forward-looking trucking company could install maintenance sensors on their trucks. Instead of a truck losing a belt and forcing a stop along the highway shoulder, the company will know to look for wear and tear on a belt even if that particular item is not included on a regular maintenance check schedule.

Trend: Self-Learning Systems

Machine-learning/self-learning is very common in some industries like eDiscovery, digital pattern detection, and sensor data analysis. The logistics sector has been slow to adopt machine learning, but forward-thinking logistics companies are adopting self-learning systems.

Self-learning logistics systems improve their algorithms as they get more data over time. The system works by recognizing patterns in data, analyzing them, and issuing accurate reports or actions. Popular usage cases for machine learning and logistics are decoding handwritten text, such as the messy handwriting often found on envelopes. The post office already makes wide use of these self-learning logistics, as do major shipping companies like UPS and FedEx.

A newer development in self-learning systems is intelligent warehouses. These systems recognize repeated trends and incidents, analyze the repeated data, connect the data to specific entities such as orders or customers, and launch pre-pack instructions. Another common example is AI and robotics that check on stock levels to reorder and restock as needed. Over time, self-learning enables the system to improve its algorithms for even more accurate responses.

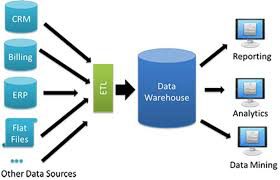

The flow of information within a company can be remarkably complex. The challenge of AI and logistics is adding an intelligent self managing element to this diverse infrastructure.

Real Life: The New Supply Chain

Artificial intelligence is fundamentally altering the rules of the logistics game. For example, transportation broker company C.H. Robinson connects with trucking companies to arrange transportation for both scheduled and last-minute loads. The company uses AI and logistics for threes usage cases: price prediction, inventory management, and managing disruptions.

● Price Prediction. Machine learning, a subset of AI, models price predictions similar to automated stock trading software. The models take historical pricing data for different types of goods, routes, and delivery schedules; cross-references them with current weather and traffic; and estimates fair prices.

● Supplier inventory management. AI analytics also track individual suppliers. The AI reports what type of freight that transportation companies carry and how much they charge. The broker filters results so they can cross-reference the type of suppliers — for example, truckers who move hazardous materials — with prices, accident reports, and cargo security. The broker maintains personal relationships with suppliers, but the AI enables the company to intelligently manage supplier inventory instead of relying entirely on past history and relationships.

● Disruption management. Highway closures, natural disasters, accidents, sick employees, and more can disrupt shipping schedules. Worse, a single disruption can ripple through a supply chain. Disruption management avoids or alleviates these events in order to deliver the goods to the destination on time and at a reasonable cost. AI predicts disruptions by feeding data from the National Weather Service, the national transportation board and law enforcement, union activities, bankruptcies, and more to predict possible delays. Machine learning enables users to train the artificial intelligence engine with a variety of contingency plans, which allows it to suggest workable solutions for a variety of possible disruptions.

Artificial intelligence and logistics may not be The Jetsons yet. But the combination is fundamentally altering supply chain management across the world.

-

Huawei’s AI Update: Things Are Moving Faster Than We Think

FEATURE | By Rob Enderle,

December 04, 2020

-

Keeping Machine Learning Algorithms Honest in the ‘Ethics-First’ Era

ARTIFICIAL INTELLIGENCE | By Guest Author,

November 18, 2020

-

Key Trends in Chatbots and RPA

FEATURE | By Guest Author,

November 10, 2020

-

Top 10 AIOps Companies

FEATURE | By Samuel Greengard,

November 05, 2020

-

What is Text Analysis?

ARTIFICIAL INTELLIGENCE | By Guest Author,

November 02, 2020

-

How Intel’s Work With Autonomous Cars Could Redefine General Purpose AI

ARTIFICIAL INTELLIGENCE | By Rob Enderle,

October 29, 2020

-

Dell Technologies World: Weaving Together Human And Machine Interaction For AI And Robotics

ARTIFICIAL INTELLIGENCE | By Rob Enderle,

October 23, 2020

-

The Super Moderator, or How IBM Project Debater Could Save Social Media

FEATURE | By Rob Enderle,

October 16, 2020

-

Top 10 Chatbot Platforms

FEATURE | By Cynthia Harvey,

October 07, 2020

-

Finding a Career Path in AI

ARTIFICIAL INTELLIGENCE | By Guest Author,

October 05, 2020

-

CIOs Discuss the Promise of AI and Data Science

FEATURE | By Guest Author,

September 25, 2020

-

Microsoft Is Building An AI Product That Could Predict The Future

FEATURE | By Rob Enderle,

September 25, 2020

-

Top 10 Machine Learning Companies 2020

FEATURE | By Cynthia Harvey,

September 22, 2020

-

NVIDIA and ARM: Massively Changing The AI Landscape

ARTIFICIAL INTELLIGENCE | By Rob Enderle,

September 18, 2020

-

Continuous Intelligence: Expert Discussion [Video and Podcast]

ARTIFICIAL INTELLIGENCE | By James Maguire,

September 14, 2020

-

Artificial Intelligence: Governance and Ethics [Video]

ARTIFICIAL INTELLIGENCE | By James Maguire,

September 13, 2020

-

IBM Watson At The US Open: Showcasing The Power Of A Mature Enterprise-Class AI

FEATURE | By Rob Enderle,

September 11, 2020

-

Artificial Intelligence: Perception vs. Reality

FEATURE | By James Maguire,

September 09, 2020

-

Anticipating The Coming Wave Of AI Enhanced PCs

FEATURE | By Rob Enderle,

September 05, 2020

-

The Critical Nature Of IBM’s NLP (Natural Language Processing) Effort

ARTIFICIAL INTELLIGENCE | By Rob Enderle,

August 14, 2020

SEE ALL

BIG DATA ARTICLES